News

- What's the difference between planetary reducer and general reducer?What's the difference between planetary reducer and general reducer? Reducer is generally used in transmission equipment, low speed high torque motor. The gear gear output shaft power internal combustion engine or other high speed running through the reducer input shaft less number of teeth on the reducer to achieve the purpose of general reducer will have several pairs of the same principle to achieve the ideal effect of gear reducer. The size of the number of teeth of the gear ratio, the transmission ratio is. Reducer is generally used in transmission equipment, low speed high torque motor. The gear gear output shaft power internal combustion engine or other high speed running through the reducer input shaft less number of teeth on the reducer to achieve the purpose of general reducer will have several pairs of the same principle to achieve the ideal effect of gear reducer. The size of the number of teeth of the gear ratio, the transmission ratio is. Reducer is a power transmission mechanism, the use of gearbox speed converter, the number of motor rotation deceleration to the desired number of turns, and get a larger torque mechanism. Function of reducer 1) reduce the speed and increase the output torque, torque output ratio by motor output multiplication and deceleration ratio, but should not exceed the rated torque of the reducer. 2) the inertia of the load is reduced at the same time, and the reduction of inertia is the square of the reduction ratio. You can see that the general motors have an inertia value. Types of reducers The general reducer has helical gear reducer (including parallel shaft helical gear reducer, worm gear reducer, bevel gear reducer, etc.), planetary gear reducer, cycloid pin gear reducer, worm gear reducer, planetary friction type mechanical stepless speed variator, etc.. Types of common reducers 1) the main characteristics of worm gear reducer is the reverse self-locking function, which can have a larger reduction ratio, the input shaft and output shaft are not on the same axis, nor on the same plane. But the general volume is large, the transmission efficiency is not high, the accuracy is not high. 2) harmonic drive of harmonic reducer is to use flexible components to control the elastic deformation to transfer movement and power, the volume is small, the accuracy is very high, but the disadvantage is that the flexible wheel life is limited, not impact resistance, rigid and metal parts are relatively poor. The input speed can not be too high. 3) planetary reducer has the advantages of compact structure, small return clearance, high accuracy, long service life, rated output torque can do a great deal. But the price is slightly expensive.

2018 05/21

- To create reducer industry to compete with the brand can be out of the low-end marketTo create reducer industry to compete with the brand can be out of the low-end market Reducer industry is basic industry of national economic development, from home appliances to cars and planes, from production tools to the mechanical transmission system of construction machinery, almost all need to use reducer. Demand pull the development of extensive machine market, but also enriches the varieties of manufacturing gear reducer. Reducer as an important component of mechanical transmission, plays an irreplaceable role in the process of China's industrial development. Common speed reducer gear reducer, according to the current situation of our country, the gear reducer from the start to the development of China today, but the effect is not very significant, the mode of production has not changed, compared with the model of gear reducer, many foreign enterprises will rely on technology, management, capital and other advantages to obtain a unique market share, and gradually enter the market Chinese reducer. In the face of foreign products in China market to seize the reducer reducer strong, industry Chinese are facing a serious crisis, and this crisis has greatly stimulated the domestic enterprises is to promote the formation of the reducer, a counterweight to the competitive mode, step by step in technology, management, increased investment, and strive to compete to foreign products, the domestic market to defend the reducer. Although this kind of passive counter reducer can temporarily keep the market share, but did not go on for long, what we need is to change from passive to active, not only to keep the original market share, but also to actively explore new markets, expand business channels. To develop a broader market, we must first ensure their own development. For enterprises, the first thing to do is to develop production, whether it is technology and management have formed a certain advantage, while stepping up the pace of independent research and development. At the same time is to create their own brand in the process of growing up, and learn to use the brand effect, because we know, influential brand is the product of the most effective weapon, but also an important symbol to have the right to speak. To create enough to compete with the brand is to focus on the development of gear reducer enterprise of our country, but also opened up a new channel for the development of the initiative, in such form, out of the low-end market will point the day and wait for it.

2018 05/18

- Don't wonder, this is the principle of speed reducer motor used!Don't wonder, this is the principle of speed reducer motor used! A reducer is a transmission between a working machine and a electric motor. To put it simply is a central overplay. Speed reducer is a kind of gearshift equipment that can change the speed and output torque, and can provide different torque and rotational speed for the equipment. If the speed ratio is 75, the output torque is about 75 times the input torque, input torque output torque speed and increase torque, rotational speed and torque is inversely proportional to the most speed ratio of the reducer is fixed, but there are adjustable, adjustable speed reducer such as car. The output power of the reducer does not change for no reason. According to the law of conservation of energy, some of its energy is converted to heat energy, and the average speed reducer works in the range of 60-98%. If a device requires slow operation, can a low speed motor be used alone? The answer is NO, because: 1. The speed is generally less than: in general, the speed of the decelerator can be as low as 3:1 or even smaller, and it can be higher than 170:1 or even higher. For example, when the motor speed is 1300 RPM, the output of the decelerator can be as high as 450 or even larger, and it can be as low as 7.5 and even smaller. Is there such a wide range for ordinary motors? Even a multi-speed motor, the fastest 2-stage motor has a rotation speed of 2,800 to 2,900 RPM, and the lowest level of the 12-stage motor is about 450-500 RPM. If you need only a dozen revolutions per minute, ordinary motors will not be able to do that. 2. The motor torque generally reach: want low work load equipment, are generally requires a larger torque (such as transfer, winding machine, etc.), even if is the speed of the machine meets the requirements, moment also can not be achieved.Do with communication server running at low speed, for example, is not a problem, but the communication server will also and other low speed motor rotating speed and load demand and torque does not conform to the requirements of the situation, if both can meet the requirements of course is the preferred solution. What if the torque doesn't meet the requirements? A. Power ac servo equipment, B. Low power ac servo device +gear motor .Solution advantages and disadvantages: option B is suitable for use of position precision without special requirement, the cost is relatively low, the price advantage obviously A solution is suitable for the position accuracy requirement, have higher defect is high cost, good precision is guaranteed; In the case of the small power ac servo device + reducer scheme, the specific defect of the speed reducer (mechanical gear has clearance) is inevitable. Each of the two schemes has its own advantages and disadvantages, and the user chooses the final plan based on the specific situation, technical requirements, capital amount and other factors. If I have an electric motor with an 800W power in my hand now, I want a speed reducer. How should I choose it? Attention should be paid when choosing: 1. Firstly, we must understand that the rated torque of our load equipment is less than the rated output torque of the reducer, or the opportunity of deceleration will be changed without moving the load. 2. Secondly, the deceleration ratio of our decelerator is not too small, and the judgment method is that the rated power of the servo motor times the deceleration ratio is greater than the load torque. 3. Finally, the speed reducer should meet the design requirements when the torque meets the design requirements.

2018 05/18

- Structure of Cycloidalreducer,gearmotorStructure of Cycloidalreducer,gearmotor. Cycloidal reducer or gearmotor is very widely used in machine industry. It mainly include three parts: input part, speed reduction part and output part. Each part also include many elements: 1.output shaft. 2.tight ring of output shaft. 3.small end cap. 4.engine base. 5.pin bush of pin roll. 6.cycloidal wheel. 7.eccentric bearing. 8.spacer ring. 9.set of pin gear. 10.shell of pin gear. 11.big end cap. 12.fan cover. 13.input shaft. We can see there is no gear inside of the cycloidal reducer. But in application that many people call it cyloidalgearmotor. Because it is looks very similar with gearmotors and has similar applications. So It is the "gearmotor" which does not have gear inside but cycloidal wheels. Cycloidal wheels working as a planetary way. This cycloidalgearmotor can give a very large ratio with a small size. It also can well suffer a big loading in a short time to avoid broken from loading sudden changes.

2018 05/17

- How to deal with the early erosion of reducerHow to deal with the early erosion of reducer The formation of point erosion is the biggest hazard to the reducer, which causes the decelerator's failure to function normally. Therefore, the enterprise should pay special attention to the formation of the early point erosion of the reducer during the use of the reducer.The staff of the JIAYOU REDUCER made the following analysis 1.In the process of speed reducer gear overhaul back pack, strictly implement maintenance procedure, to ensure each gear installed, remove the contact parts of material at the same time, adjust good gear axial clearance, to ensure that the gear tooth contact area, improve the accuracy of speed reducer gear contact. 2.Reducer gear lubricant, should strictly according to the required type reducer itself lubricants for lubrication, prohibited to use different types of lubricant blending, at the same time guarantee the quality of lubricant, outstanding for metamorphism of lubricant is strictly prohibited. 3.Reducer gear strictly enforce standards on material selection, can't choose those unqualified material quality, at the same time in the process of gear heat treatment, for those who are not qualified gear products, resolutely give fall into disuse. 4.In early use process in addition to pay attention to the various items of from time to time to cleaning of reducer, gear box of gear case of machine cleaning maintenance using the original to the discharge of oil system and the filtered oil to wash of gear box, not any hardware change gear box, do not add any detergent, ensure the safety of the gear box operation, prolong the service life of the gear box. It can guarantee the normal operation of the reducer.

2018 05/17

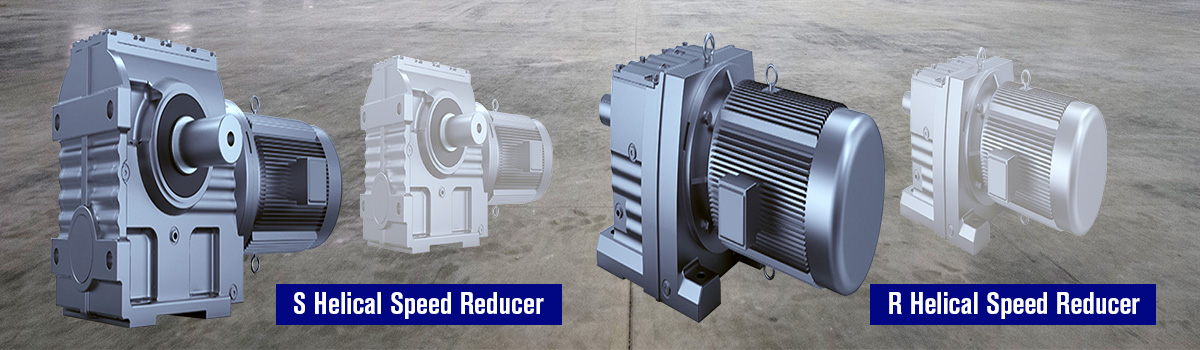

- JiaYou helical reducerJiaYou helical reducer Helical gear and bevel gear reducer 1. The G series adopts the whole body structure, and the six surfaces are reserved for mounting holes, which are beautiful and durable, and can withstand heavier loads. 2. Modular assembly customization, compact structure, ensuring high torque transmission. 3. The best sealing arrangement and structure are combined, the bearing life is long, and can realize horizontal, vertical and vertical multiple installation forms. 4. K helical gear and bevel gear - helical gear reducer 5. Oblique gear and bevel gear - helical gear reducer is the most complete and decelerated speed reducer in the current market. The output speed range can reach 0.04-1108RPM 6. Product classification refinement, cooperate with the adapter flange, non-return device, such as motor and pump shaft end seal system, such as large low speed shaft flange modular attachments, wide range of its application scope, so as to realize using minimal parts can meet the demand of a variety of conditions. This product series is widely used in mining, building materials, chemical industry, electric power, metallurgy, food and feed, transportation, paper making and environmental protection industries.

2018 05/16

- A brief analysis of the prospect for demand of the robot industry for REDUCERA brief analysis of the prospect for demand of the robot industry for REDUCER The robot industry is the most high-profile industry in the world today. The precision reducer is the most important functional component in industrial robot, and it is an important part of the robot industry chain. From 2015 to 2018, according to the national authority` forecast, the number of new demand for transmission reducer of our industrial robots is expected to be 236,000, 296,000, 369,000 and 462,000 sets. In addition, for the industrial robots that are kept in the domestic market, the market demand for precision reducers will exceed 1 million in the future, and the annual market sales will exceed 10 million yuan. China became the main battleground in the international reducer industry. After more than 40 years of market development and decline, China's reducer products have developed from the original cycloidal speed reducer to the current gear reducer, worm gear reducer, etc., and have been widely used in various fields of power machinery, metallurgical machinery,environmental protection machinery, chemical machinery, food machinery, mining machinery, construction machinery, water conservancy machinery and other fields in national economy, which are highly favored by the market. After several generations of joint efforts, China's reducer industry has formed a huge industry scale. At present, China's speed reducer products not only meet the needs of the domestic mainstream market, but also sell abroad and occupy a certain position in the international market, which is known to all over the world. China has become a major country in the world's reducer mechanism. With the continuing drive of the national macro-control, our country's reducer industry has grown into the main battlefield of the international reducer industry. The world famous enterprises have entered China's decelerating machine market, and with the superior brand, abundant capital, advanced technology and equipment and other advantages, the competition with domestic reducer enterprises is fierce. However, the domestic enterprises mainly engaged in the production of general speed reducer are less involved in industrial special speed reducers field, and the industrial technology is not mature. Therefore, in the competition with foreign advanced enterprises, China's reducer enterprises will have to experience a long period of market sharpening in order to occupy the dominant position of market competition. The slow recovery of the world economy has reactivated the global consumer market. At the same time, the impact of China's macroeconomic policies and the strengthening of infrastructure investment will inevitably drive the growth of demand for reducer in industries such as metallurgy, electricity and construction machinery.

2018 05/13

- Iran's steel industryIran's steel industry Iran is at the intersection of the "One Belt, One Road" and is expected to continue its cooperation with China in such fields as infrastructure, connectivity, production capacity and energy under the Belt and Road Initiative. In recent years, with Iran's emphasis on the steel industry, it has further increased its investment in the domestic steel industry and also brought investment opportunities to Chinese steel enterprises. Also brought us the opportunity to JiaYou, JiaYoureducer is widely used in the steel industry. It is understood that in 2015 Iran's crude steel output was 16.146 million tons, 23.7 million tons capacity, capacity utilization close to 70%, ranked No. 14 in the world crude steel production rankings. Since 2008, Iran's crude steel production increased dramatically. According to calculations, between 2006 and 2015, Iran's crude steel production has doubled, and this is still achieved under the environment of economic sanctions. According to the study, the output of pig iron in Iran blast furnace did not change much in the past 10 years, while the proportion of pig iron in blast furnace dropped from 22.8% in 2006 to 14.4% in 2015, while the proportion of DRI increased steadily from 77.2% Rising to 85.6% in 2015. It is mainly due to the comparative advantage of the DRI development in Iran. The first is lower energy costs and abundant natural gas resources. The second is that it has a wealth of iron ore resources. Almost all of Iran's major steelmakers are wholly or partly part of the government-owned Iran Mining Development and Reform Organization (IMIDRO), which plays an important role in shaping Iran's strategy for the metal mining industry. Among them, the three most important steelmakers are Esco, Mobarakeh and Khouzestan. In addition to the three major steel mills, there are 20 private mills in Iran that mainly import billets from the Commonwealth of Independent States, such as West Asia Steel, Kerman Iran Steel), Iran Arfa Steel and so on. We hope our JIAYOU will vigorously develop in Iran in steel industry.

2018 05/13

- Speed Reducer and automation equipmentSpeed Reducer and automation equipment At present, the precision reducer is mainly used in industrial robot, textile machine,mining machine numerical control machine tool and automation equipment. In the next few years, China's industrial robot industry will be at a rapid development stage, which provides a broad market prospect for high-precision and high-performance joint reducers. Unfortunately, China's robot precision reducer has long relied on imports. The good news is that this is about to change. Research through the industry's "tracking" and "independent innovation", and the strong support of the government, many kinds of robots in the RV and industrialization of harmonic gear reducer is real advance in the next three years will form the production capacity of 1 million units, will support the development of robot and intelligent equipment industry in China. China's high-speed train is a "golden card" made in China. Behind the rise of high-end equipment in China, however, is the lag behind key components. The gearbox is the core component of the power transmission of high-speed train, and its performance directly determines the reliability and safety of high-speed train operation. The world's high-speed gear boxes have been completely monopolized by companies such as Germany and Japan. Compared with abroad for high-speed rail, China's high-speed trains because of the wide north-south temperature difference, running, long span, high speed, long running, such as complicated working condition, on the gearbox reliability performance more stringent requirements are put forward. To solve the constrained the gear box of high-speed development, our country related enterprises in the national support, another stream diameter, solved the Gao Tieyong gearbox temperature rise, vibration, lightweight, reliability and other problems, formed the integrated design method, developed with independent intellectual products, replaced the foreign products, has achieved industrialization. The gear industry enters the fourth development, independent innovation becomes the main melody. The author investigated that the first three times in China's gear industry mainly benefited from the introduction, digestion and re-innovation. And the fourth pole of development provides the opportunity for the re-shuffling of the gear industry. The new leading enterprises will stand out, and some of the old enterprises will lose their development opportunities and even exit the market. It should be said that at present the fourth growth pole in gear industry, domestic related equipment industry can not meet this need, and the cog-wheel industry related industry should seize the opportunity, develop their own, at the same time, in turn, promote the development of the fourth gear industry is extremely more quickly. These bases include the talent base, the technical foundation, the management base and the supporting foundation of the industrial chain.

2018 05/13

- There are 30 reasons for the bearing noiseThere are 30 reasons for the bearing noise Bearing is an important part of the speed reducer,sometimes the bearing will have noise. The engineer from JiaYou REDUCER reducer made the following summary: 1.Grease contamination 2.Insufficient lubrication (the oil level is too low and the oil or grease can be damaged by sealing by improper preservation) 3.The clearance of the bearing is too small or too big (production plant problem); 4.The bearing is mixed with sand or carbon granule, which ACTS as abrasive 5.The bearing is mixed with moisture, acid or paint, which can be corrosive 6.The bearing is flattened by a hole. (the hole is not well rounded, or the hole is distorted.) 7.The underside of the underside of the bearing seat is uneven (leading to a hole deformation and even a crack in the bearing seat) 8.Bearing holes (residual chips, dust particles, etc.) 9.Eccentricity of sealing ring (touching adjacent parts and friction) 10.The bearing is subjected to additional load (the bearing is under a tight shaft, or a shaft has two fixed end bearings); 11.The bearing and shaft alignment is too loose (the diameter of the shaft is small or tight); 12.The clearance of the bearing is too small, and the rotation is too tight. 13.Bearing noise (the end of roller or the sliding of steel ball) 14.The heat elongation of the shaft is too large (bearing is subjected to the static axis to the additional load) 15.The shaft shoulder is too big (contact the seal of bearing and friction); 16.The shoulder of the seat is too large (the sealing part of the bearing is distorted); 17.The clearance of labyrinth seals is too small (friction with shaft) 18.The tooth of the lock washer (touching the bearing and the friction); 19.The position of the oil dump is not suitable (touching the flange cover and friction) 20.A hole in a ball or roller.Hammering the bearing with a hammer when installed 21.Bearing noise (external vibration source interference) 22.The bearing is heated and discolored (caused by the use of a spray gun to heat and disassemble the bearing) 23.The shaft is too thick to make the actual match too tight (causing the bearing temperature to be too high or noise); 24.The diameter of the seat hole is small (the bearing temperature is too high); 25.The bearing hole diameter is too large, the actual match is too loose (the bearing temperature is too high - the outer ring is skidded). 26.The bearing hole becomes large (the bearing hole of the nonferrous metal is enlarged or enlarged due to thermal expansion); 27.Stand fracture 28.Bearing roller is rusted. 29.Steel ball, raceway wear (the grinding is not qualified or the product has a collision). 30.Non-conformity (production plant problem)

2018 05/12

- The price of the Asian original material of plastic would arrive the top before Chinese National DayThe price of the Asian original material of plastic would arrive the top before Chinese National Day The marketing specialist said the price of the Asian original material of plastic would arrive the top before Chinese National Day. Because both the buyers and Chinese traders would try best to look for the prompt goods before the long Chinese national day. And their buying will is very strong. It is said that the bargaining interval of the ABS in Asian market is between 1550 USD and 1640 USD. (CFR south-east Asia). We get the news from one trader that there are many trade activities and price discussing of butadiene in this week. Because the marketing activities would be less slowly before the Chinese National Day Chinese market would close down from 1st October to 8th October for Chinese National Day. And we get the news from marketing people that the sales tender of 2000 tons ABS plastic original material provided in October from Lotte Chemical Titan Malaysia already attracted so many bidders. Anfast data shows that the price of butadiene in Asia already increase a lot. The price increased 550USD/ton from the end of July. It is about 58%. Till 8th Sept, the price increased to 1500 USD/ton.(CFR south-east Asia) According to a synthetic rubber, the ABS plastic original material would still increase before the long holiday coming. But once the holiday arrives, the price would be down. The plastic original material price fluctuates strongly. People do not know the marketing after the long holiday. So people should be cautious when purchasing or holding the goods.

2018 05/11

- JiaYou has successfully developed the South China Sea the development of marine special reducerJiaYou has successfully developed the South China Sea the development of marine special reducer In the seven Assembly plant of JiaYou cooperation, a unique cylindrical gear reducer type CJ1596 with size of length 8 meters, width 2.8 meters and height 3 meters, gross weight 40 tons, which designed by the JiaYou Technology Center , has been successful Assembly and ready to be sent to customer. The gear reducer is specially developed for marine of the South China Sea development, as well is one of a representative special reducer product, designed by JiaYou. By means of China's Maritime dream and constant attention and depth of the development of marine field of China state, besides the reducer has a large carrying capacity, safe and reliable, and other significant characteristics, therefore, its future market prospects must be very broad. The good news is that although these special reducers need high technical requirements and complex production process. The customer ``s requirements for the acceptance and use standard of the products are extremely strict and high, but with more than 24 years` experience in production gear motors, JiaYou has successfully gone through the test and won the trust of customer.

2018 05/11

- Three directions of China reducer transformationThree directions of China reducer transformation At present, China is in a transition period of economic and social development. As the "old industry" , it is necessary to make a certain example to promote the smooth transition of China's economic and social development. China reducer industry restructuring can proceed from the following three directions: First of all, with the national support for green reducer, reducer industry should pay attention to the transformation and establishment of a sound innovation system and mechanism, adhere to the refinement of the chemical industry, recycling, equipment manufacturing industry intelligence, high-end, biomedical industry, serialization, emerging industries, high-end, integrated as the core, to jointly promote the healthy and efficient development of the industry. Secondly, reducer enterprises should strengthen cooperation with the large consortia in China and abroad. At present, the economic situation in foreign countries is not optimistic. Innovative reducer enterprises should support large projects and good projects and continue to increase investment in technical and professional personnel. They will continue to form "attracting large projects, cultivating large enterprises, gathering large industries and building large Park "development strategy. Finally, the industry should cultivate the brand and apply for a patent, speed up the construction in the soft environment of transformation and upgrading and innovation and development. Speed reducer Economic sectors Mechanical transmission device involved in the product categories include all types of gear reducer, planetary reducer and worm reducer, including a variety of special transmission device speed devices, speed devices, including flexible transmission device within the various types of complex Transmission devices and other product services related to metallurgy, coal, building materials, ships, water conservancy, electricity, construction machinery and petrochemical industries. The company is located in: The development of the industry requires not only the coordination of the industrial chain, the establishment of an innovative system, but also the driving force of the leading enterprises. When the power is gradually increased, the continuous operation of benign ability, the development of the industry will continue to improve, upgrade, toward healthy and efficient development.

2018 05/10

- The 30 - load gear industry ushered in the development of the fourth stageThe 30 - load gear industry ushered in the development of the fourth stage The gear is a key basic component of large scale, which is applied to almost every field of national economy. Gear industry is a technology intensive and capital-intensive industry in the machinery industry. At present, the gear industry has become the largest industry in China's mechanical infrastructure. Last year, the output value of the national gear industry was about 230 billion yuan, ranking first in the world. Over the past 30 years, China's gear industry has experienced rapid development, with an average growth rate of 18%. In the past three years, the entire industry has been in the middle of a long period of growth, and the deficit has widened. It should be said that the past three years have also been a period of hard work in the gear industry, technological innovation and transformation and upgrading. On the occasion of the opportunities China general gear parts association branch (that is, the China association of specialized gear CGMA) has held its 2017 national gear technology seminar in zhejianghuzhou, is designed to lead industry comprehensive development of independent innovation, industry experts, entrepreneurs gathered GongYi future development. CGMA vice President and deputy secretary-general, Beijing university of technology professor stone upon admitted that the long-term development of the industry a comprehensive breakthrough on key technologies, improve product quality, the country's economic transformation and upgrading of opportunity, China's gear industry ushered in the new stage of development. More importantly, China's gear industry has formed the most complete industrial system in the world, which can be said to cover the whole field of gear products. With the current development trend, the industry will reach 300 billion in the next five years. 25 years ago, the development of the motorcycle gear made the production value of the gear industry in China from a few billion yuan to more than 20 billion yuan. Sixteen years ago, with China's entry into the WTO as a connecting flight, the development of the automobile gears brought the production value of the gear industry in China to about 130 billion yuan from tens of billions of yuan, which is the second pole of the development of the gear industry. A decade ago, the development of wind power and construction machinery gear led to a third pole of growth in the gear industry, bringing the production value of the gear industry up nearly 200 billion yuan. The development of the fourth pole is the comprehensive industrialization of the domestic automatic transmission, the precision reducer and the gearbox of high-speed train.

2018 05/09

- How to deal with mounting and lubrication of gear motorsHow to deal with mounting and lubrication of gear motors Installation and usage of Gear reducer is directly related to its operating results, so it must follow the technical specifications and standards. As a power transmission structure, the normal operation of gear reducer is inseparable with the lubricating oil, so during using, we should also pay attention to the gear reducer's lubrication. The following are considerations about gear reducer installation and lubrication: 1. Mounting 1) Gear reducer is generally to be installed in the horizontal level, amount of inclination should be no more than 10°. If need amount of inclination more than 10° in special cases, , please contact the manufacture to discuss matters before using. 2)When connect the input and output shaft with the power and working machine, if use couplings, shafts should be aligned strictly, there shall be no decentration.When using the V-belt and chain ,it should not be too tight or too loose. 3) The installation foundation should be strong and reliable without vibration and loosening. The screws should be strictly in accordance with the relevant standards. 4) Inspect tightness of the screws, try to use a spring washer. 2.Lubracation 1) Generally uses oil pool lubrication for gear reducer. Add good extreme pressure gear oil N220 or N320 to a predetermined position (20-30mm upper the low gear portion) before using, and add regularly. 2) For first using 50 hours, should immediately replace with new oil, and clean the oil inside the body. After that completely replace once every three months. 3) Replace the oil seal leak as soon as possible when there is oil leakage. JiangYinJiaYou reducer Co., Ltd. is a professional high-tech company, which is engaged in precision transmission products R & D, production and sales of high quality gear motors. JiaYou is based on strong economic strength and superb technical support, as well as modern management concept and constantly strives for innovation and excellence business purpose to provide high quality products, excellent after-sales service to create maximum value for customers.

2018 05/09

- The development process of speed reducerThe development process of speed reducer In the 1970s and 1980s, there was a great deal of speed reducer in the world, and it was closely integrated with the new skills revolution. The trend of general motors is as follows: High level and high performance. The cylindrical gears can be made of carburized quenching and grinding teeth, and the bearing capacity can be more than four times, small size, light weight, low noise, high power and high reliability. Modular assembly planning. The basic parameters are selected with priority number, standard scale standard, and the versatility and interchangeability of parts. The series is simple extension and variety renovation, which is conducive to the arrangement of batch production and cost reduction. The type is diversified, the variation plan is much. Equipment to get rid of the traditional single base, added a hollow shaft hanging, floating bearing base, motor and reducer, one-piece connection surface multi-azimuth equipment such as different types, expand the use range. The main factors that promote the progress of decelerator are: The theoretical knowledge is becoming more and more perfect, which is more closely based on practice (such as gear strength accounting method, repair skill, deformation accounting, optimization planning method, root oil slip transition, new layout, etc.). With good data, all kinds of high quality alloy steel forgings, data and heat treatment quality control can be improved. The layout plan is more reasonable. The machining accuracy has been improved to the ISO 5-6 level. The quality of the bearing and the progress of longevity. Improve the quality of lubricant. Since 20 century 60 times, China has successively developed JB1130-70 the cylindrical gear reducer, a batch of universal standard reducer, in addition to supporting forms a cheap use, also formed a batch of reducer professional production factory. At present, there are a few hundred companies producing speed reducers nationwide, with a yearly output of about 250, 000 engine reducers, and dedicated to the development of Chinese mechanical products. 20 centuries 60 time reducer are mostly refer to the skills of the Soviet union in the 20th century 40-50 times, though they have carried out later, but limited to planning, technological level, and equipped with conditions at that time, and its overall level and international level has great distance. Since China's reform and opening up, China introduced a number of leading processing, after introducing, digesting and absorbing foreign leading skills and scientific research, and gradually mastered all kinds of high-speed and low-speed gears equipment planning construction skills. Materials and heat treatment quality and have significant progress, the gear machining accuracy of general production precision cylindrical gears are available from JB179-60 8-9 grade progress to level 6 GB10095-88, production of high-speed gear accuracy can be stable in 4-5. Some slowdown after the pause in the hard tooth face, significantly reduce the volume and quality, bearing ability, using the full, transmission power had great progress, to host the overall level of energy saving and progress have very big effect. The power of China's self-planning high-speed gear reduction (increase) speed device has reached 42000kW, with the speed of the gears reaching 150m/s. However, most of China's decelerator skills are not high enough, and old goods cannot be replaced immediately, and the transition of old and new goods will be a long time.

2018 05/08

- What are gear motor using skillsWhat are gear motor using skills JIAYOU REDUCER CO., LTD is a company that develops and produces gear transmission mechanism products, and produces high quality reduction gearbox, gearbox motor, decelerating motor and other products. Gear motor is most people are not unfamiliar, deceleration motor between prime mover and work machine or actuator has a function in matching speed and transfer torque is a relatively sophisticated machinery. However, due to the poor working environment of decelerating motor, the failure of wear and tear can often occur. What is the use of decelerating motor ? To avoid failure, we need to understand the use techniques of decelerating motor. First, the user should have the use of reasonable maintenance rules and regulations, the deceleration of the motor running situation and the problems found during the inspection should be done carefully record in work, when they discovered oil [rises more than 80 ℃ or oil pool temperature over 100 ℃ and produce the phenomenon such as abnormal noise should stop using, check the reason, have to troubleshoot, after oil change, may continue to operate. Second gear motor, oil change wait for cooling down without burning dangerous, but should still keep warm, because completely cooled, the oil viscosity increase, oil drain difficult. Note: to cut off the transmission power, prevent inadvertently electricity. Three, in 200 ~ 300 hours after operation, the first oil change should be made, in use should be regularly check the oil quality, to mix impurities or bad oil must be timely replacement. In general, long-term continuous work for a slowdown in motor, according to run 5000 hours, or once a year to replace the new oil, stop using deceleration of the motor for a long time, is also a new oil should be replaced before the function again. Gear motor should join the same as the original brand oil, may not be used with different type of oil phase, the same brand but different viscosity oil allow mix.

2018 05/05

- The market of robot reducer is restricting the development of the industryThe market of robot reducer is restricting the development of the industry According to the growth of sales volume and volume of industrial robots, the demand for industrial robots is expected to reach 10.5 million by 2025, and the demand scale will be around 7.7 billion yuan. But heavy reliance on imported, as well as the technology is not mature, makes the reducer become the key factor restricting the development of robot industry in China, thus conquer technology is the inevitable choice of domestic robot enterprises industrialization. As the most central feature of industrial robots, the reducer accounts for 33% to 38% of the total cost of manufacturing robots. The current industrial robot sector is in the ascendant, sales are soaring, the potential demand of decelerator is climbing year by year. Gear motor to industrial robots Arguably, the power source of the industrial robot for ac servo motor, commonly as driven by the pulse signal, the servo motor itself can realize speed regulation, why industrial robot reducer is needed? In order to ensure the industrial robots in production can be reliably process task, and ensure the process quality, the positioning accuracy of industrial robots and repeated positioning accuracy is very high, and need to improve and ensure the accuracy of industrial robots is using precision gear reducer. The existence of precision speed reducer makes the servo electric at an appropriate speed running, and accurately will speed to the speed of each part of the industrial robots need, improve mechanical rigid body greater torque output at the same time. Compared with the general reducer, the robot joint reducer requires the characteristics of short drive chain, small volume, large power, light weight and easy control. The decelerator market is developing rapidly .In recent years, the rapid development of domestic economy, the export volume of heavy machinery industry has increased, and the development of decelerator industry in an important basic industry has been extremely rapid. Because of the downstream market forces, the decelerator enterprise is expanding to the production and marketing scale, the processing ability and the technical level continue to improve. According to the growth of sales volume and volume of industrial robots, the demand for industrial robots is expected to reach 10.5 million by 2025, and the demand scale will be around 7.7 billion yuan. According to the national authorities, the number of new demand for speed reducers in China will be 236,000, 296,000 sets, 369,000 sets and 462 000 sets in 2015. In addition, for the domestic market to keep the service life of the industrial robot according to the general 8 years to 10 years, the domestic demand for precision reducer will more than 1 million units, annual sales will exceed 10 billion yuan of above. Technology hobbled the industry . Globally, the market for robot reducers is dominated by Japanese companies, and other countries have limited capabilities. According to statistics, Japan's sumitomo, nabisco and hammurakko have accounted for more than 80% of the global market share and are in absolute monopoly. As far as China is concerned, the research on the robot reducer is late and the technology is not mature. It is now heavily dependent on imports, and although it has increased in recent years, it still has a distance. It can be said that the decelerator is the key factor that restricts the development of China's robot industry, and it is the inevitable choice for the industrialization of domestic robot enterprises. At present, the domestic decelerator has been evaluated in the market for 3-4 years, and the main test in performance is noise, precision and stiffness. With the development of the robot industry, domestic manufacturers realized the importance of the reducer and made continuous progress. In the aspect of harmonic speed reducers, domestic manufacturers such as green harmonics have gradually narrowed the gap with foreign products, and are constantly seeking breakthroughs in the RV reducer. In the future, with the development of industrial robots, China's robot decelerator industry is expected to develop rapidly and market demand is constantly released. However, for domestic enterprises, the development of localization still has a long way to go, and the future can be properly tilted to harmonic reducers to realize the curve overtaking.

2018 05/03

- Daily maintenance methods for JiaYou speed reducersDaily maintenance methods for JiaYou Motor reducers In order to ensure the motor reducer`s normal operation, except for the monitoring and maintenance during the normal use according to the rules, regular checking should also be done for motor reducer maintenance. In this way can timely eliminate some problems, prevent the fault occupation, and ensure the motor reducer safe and reliable operation. Intervals of periodic maintenance may vary according to use environment of the motor reducer. Regular maintenance methods are as follows: 1.Clean the motor reducer. Timely remove external dust, oil and mud on the basement part of motor reducer. If there is much dust in the using environment, it`s better to clean once a day. 2.Inspect and clean the motor reducer terminals. Check whether wiring screws in the junction box are loose or burned. 3.Check the fixed screws, including anchor screws, end cap screws, bearing cap screws etc. Tighten the loose nut. Check the driving device, belt wheel or the coupling for cracks and damage, whether installation is firm; the belt and the coupling buckle whether are in good condition. Bearing inspection and maintenance. After a period of time of using, bearings should be cleaned, replace the grease or oil. The time for cleaning and changing oil is decided on the work environment, cleanliness, the lubricant type of the motor reducer. Generally it should be washed once and re-change the grease every 3-6 months.

2018 05/02

- Robot and speed reducerRobot and speed reducer The robot industry is the most high-profile industry in the world, and the development space is self-evident. The precision reducer is the most important functional component in industrial robot, and it is an important part of the robot industry chain. According to the national authority's forecast, in 2015 -- 2018, China's industrial robots will demand a total of 236,000 units, 296,000 sets, 369,000 sets and 462 000 sets. In addition, for the domestic market to keep the service life of the industrial robot according to the general 8 years to 10 years, the domestic demand for precision reducer will more than 1 million units, annual sales will exceed 10 billion yuan of above. Industry insiders believe that overall, the robot decelerator industry has a promising future, and the potential demand is huge. To this end, domestic manufacturers are increasing their layout. As the necessary transmission equipment in modernization construction, reducer is widely used in various fields of national economy. For the robot industry, the speed reducer is a vital part of the industrial chain. Thanks to the rise of the robotics industry, the robot slowdown is expected to drive into the fast lane. In the future, with the development of industrial robots, China's robot decelerator industry is expected to develop rapidly and market demand is constantly released. However, for domestic enterprises, the development of localization still has a long way to go, and the future can be properly tilted to helical reducers to realize the curve overtaking.

2018 05/01

Email to this supplier